Korea Institute of Civil Engineering and Building Technology has developed the world’s first shear-thickening-fluid–based (STF) stemming solution. This is the first time that an STF has been developed into a blasting construction material or product for stemming, promising to revolutionize construction blasting with groundbreaking levels of efficiency and safety.

Blasting is a crucial process in both mining and construction. However, low blasting efficiency has been an issue that has long plagued the blasting industry. Low blasting efficiency is when the target (most commonly rock) is not well broken down compared to the mass of explosives used. Selecting the right stemming material plays an important part in optimizing blasting operations, allowing reduced costs and enhancing the productivity and profitability of excavation and mining.

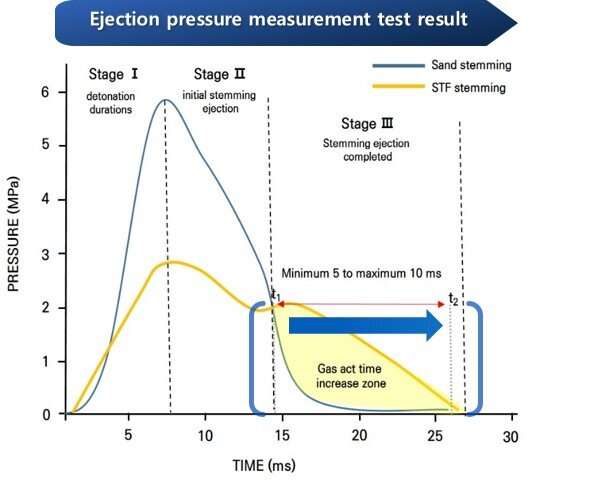

Stemming is a process in industrial blasting in which a blasting hole is sealed with stemming materials to prevent the leaking of explosion gases from the blast hole. The use of inadequate stemming materials can lead to over 50% of the explosive energy being lost during a blasting operation. On top of the economic loss incurred by the waste of resources, the excess energy that leaks into the outward is converted to ground vibrations and noise, which may even cause environmental damage.

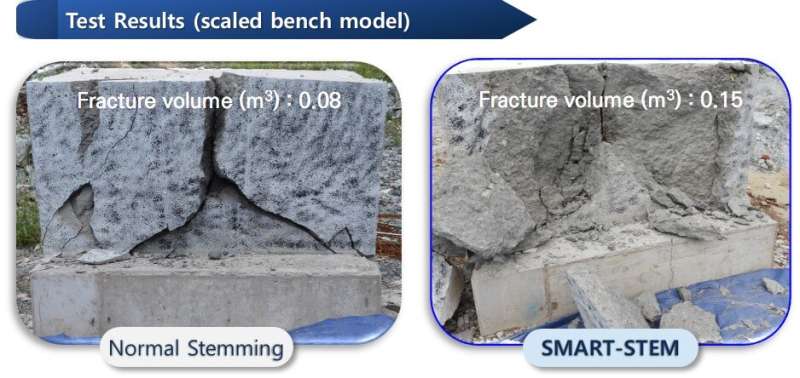

This STF-based stemming solution has been named SMART-STEM by the team of KICT researchers who developed it. The research team at the KICT Department of Geotechnical Engineering Research (Dr. Moonkyung Chung, Dr. Younghun Ko, Dr. Seunghwan Seo) performed numerous tests over a period of three years from 2020 onward. The findings, published in Applied Sciences, showed that SMART-STEM increased resistance to the eruption of explosive gases by 330% compared to the conventional sand-based stemming materials, while rock blasting performance was improved by more than 60%.

On-site demonstration of tunnel blasting in urban centers with high population density was also completed through a third-party validation test conducted in August 2022 in a very deep underground urban expressway construction site in Busan, South Korea. The excavation rate per blast increased greatly, with a reduction in total explosive consumption of up to 20%, leading to a reduction of ground blasting vibration in residential area of up to 50%.

The newly developed SMART-STEM offers consistently robust and uniform sealing performance, reducing explosive consumption in blasting sites by simply substituting the existing stemming material with an affordable STF-based material. Moreover, with enhanced tunnel excavation rate per blast and reduced secondary work time, it can help reduce construction costs by up to 17%.

The lead researcher of the project, Dr. Moonkyung Chung, commented, “I anticipate SMART-STEM to be utilized as a mainstay of tunnel construction and other blasting projects in the urban centers of Korea. The construction blasting industry will be able to achieve more efficiency and effectiveness in blasting projects, raising their productivity and profitability by adopting the SMART-STEM technology.

SMART-STEM was developed by a research team at the Korea Institute of Civil Engineering and Building Technology as a task under one of the institute’s key projects, “Development of new stemming material and blasting method using shear thickening fluid by high shock wave reaction.”

More information:

Younghun Ko et al, Blast Hole Pressure Measurement and a Full-Scale Blasting Experiment in Hard Rock Quarry Mine Using Shock-Reactive Stemming Materials, Applied Sciences (2022). DOI: 10.3390/app12178629

Provided by

National Research Council of Science & Technology

Citation:

Shear-thickening-fluid–based stemming solution for the construction blasting industry (2023, March 22)

retrieved 22 March 2023

from https://techxplore.com/news/2023-03-shear-thickening-fluidbased-stemming-solution-blasting-industry.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.