With the growing demand for electric vehicles, the need for high-safety, long-life batteries also rises. Yet electric vehicles’ demand for high energy density batteries outpaces the capabilities of the current lithium-ion batteries. Scientists are looking to develop lithium metal batteries with lithium metal as the anode because these batteries have a much higher charging capacity. However, there are safety issues with lithium-metal batteries because dendrites—spiky, metallic microstructures—form during the charging process.

A team of Chinese researchers set out to solve the problem of the lithium dendrite formation and to build high-safety, long-life lithium metal batteries. The team has successfully designed an electrolyte that suppresses the formation of the dendrites. This electrolyte delivers excellent performance in lithium metal batteries and offers solutions in the research toward building high-safety, long-life lithium metal batteries.

The team’s findings are published in the journal Nano Research.

While lithium metal anodes hold great potential for high-energy storage batteries, the uncontrollable lithium dendrite growth raises significant concerns. The dendrite growth occurs when the lithium ions move and convert to one specific location on the lithium metal surface. The dendrites cause poor cycling efficiency in the battery and are a severe safety issue.

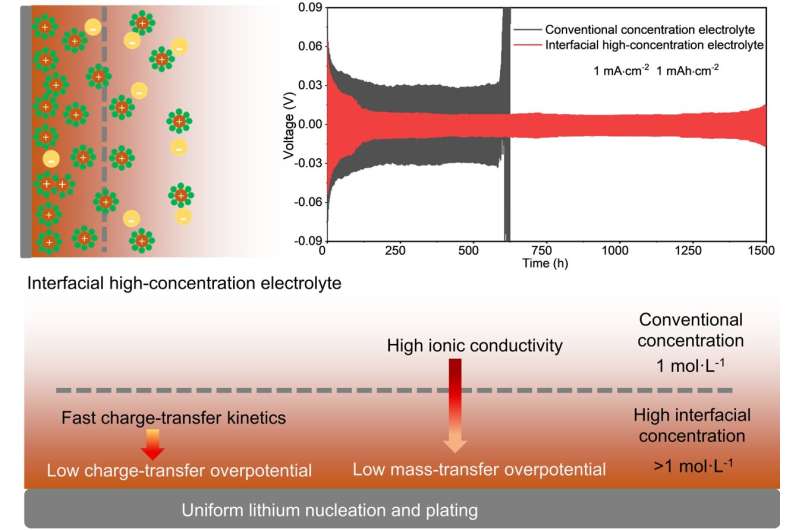

The team tackled the dendrite problem by combining the advantages of conventional electrolytes and high-concentration electrolytes. The high-concentration electrolytes overcome some of the shortcomings of conventional electrolytes, and hold strong promise for use in next-generation batteries.

The electrolyte the team created delivers excellent electrochemical performance in lithium metal batteries and suppresses formation of dendrites. “Its unique structure not only promotes the uniform conversion of ions on the electrode surface but also ensures the rapid movement of ions in the electrolyte,” said Chunpeng Yang, a professor at Tianjin University.

The researchers began their work by running numerical simulations to explore the effect of a negatively charged coating to induce the interfacial high-concentration electrolyte. Then as a proof-of-concept material, the researchers coated nitrogen- and oxygen-doped carbon nanosheets, that have surface negative charges, with nickel foam to create the electrode.

The positively charged lithium ions are concentrated near the nitrogen- and oxygen-doped carbon electrode that is coated with nickel. This concentration of lithium ions promotes the charge transfer reactions on the electrode contribute to outstanding electrochemical cycling performances. The researchers conducted half-cell and full-cell tests on the electrode with excellent results. Their electrode performs much better than other electrodes based on pure nickel foam.

“This provides a simple principle for suppressing the lithium dendrites by simultaneously taking into account the advantages of conventional electrolyte and high-concentration electrolyte for stable Li metal anode, which may be applied to other substrates for practical metal batteries,” said Yang.

Beyond coating negatively surface-charged materials on the electrode to guide the formation of interfacial high-concentrated electrolytes, the team plans to look for other ways to obtain this unique electrolyte structure as means to achieving high-performance batteries.

The researchers hope to achieve the commercial application of Li metal batteries with high energy density, high safety and long life, by systematically optimizing the battery components. “Our study results could be extended to more metal-battery systems, such as sodium, zinc and magnesium metal batteries, which will contribute to the realization of large-scale energy storage for sustainable energy supply,” said Yang

Reactive electrolyte additives improve lithium metal battery performance

Haotian Lu et al, Interfacial high-concentration electrolyte for stable lithium metal anode: Theory, design, and demonstration, Nano Research (2022). DOI: 10.1007/s12274-022-5018-7

Provided by

Tsinghua University Press

Citation:

Scientists design electrolyte for lithium metal anodes for use in lithium metal batteries (2022, October 7)

retrieved 7 October 2022

from https://techxplore.com/news/2022-10-scientists-electrolyte-lithium-metal-anodes.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.