Metallic lithium is considered as the ultimate anode material of next-generation high-performance energy storage system, owing to its ultrahigh theoretical specific capacity (3860 mA h g-1), ultralow electrochemical potential (-3.04 V vs. the standard hydrogen electrode), and low density (0.534 g cm-3).

Employing Li metal as high-capacity anode, solid-state lithium-metal batteries (SSLMBs) are becoming one of the most promising candidates for next-generation energy storage devices, due to their high safety and potential high energy density. SSLMBs are expected to be the future for conventional lithium-ion batteries.

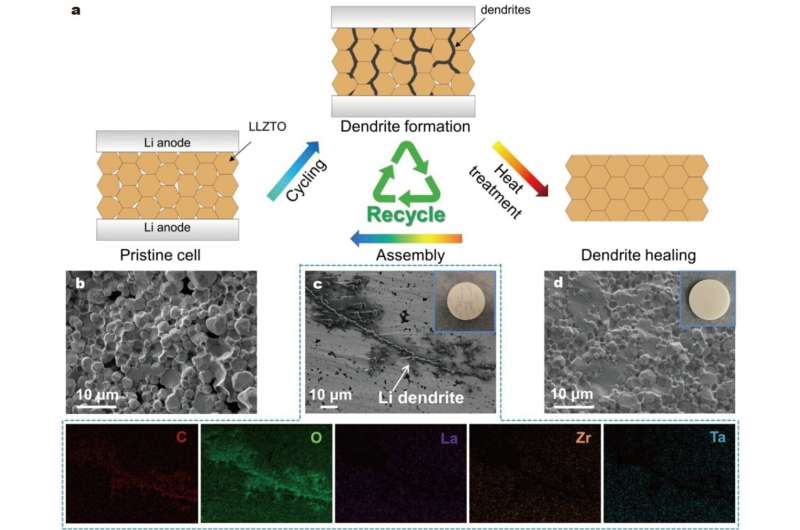

However, the development of SSLMBs is still limited, due to the severe safety issues caused by the uncontrolled Li dendrite formation and growth. Additionally, the strategies focusing on healing or recycling solid electrolytes with Li dendrite penetration are rarely reported.

Recently, a study was led by the group of Prof. Wei Liu (School of Physical Science and Technology, ShanghaiTech University). In this study, they demonstrate a facile method for healing and recycling garnet electrolytes (Ta doped Li7La3Zr2O12: LLZTO) with Li dendrites through heat treatment.

Excitingly, the recycled garnet ceramic pellets have increased ionic conductivity with higher relative density, which is due to the dendrite-derived species (LiOH and Li2CO3) in the grain boundaries are able to promote further densification of garnet electrolyte pellets during thermal healing process as sintering aids.

Compared with pristine garnet electrolyte pellets, the relative density of the recycled garnet pellets is improved from 90.9% to 95.3%, and ionic conductivity is improved from 0.39 to 0.62 mS cm-1. Benefiting from the enhanced relative density and ionic conductivity, a higher critical current density (CCD) is achieved, suggesting a better suppression effect on Li dendrite penetration.

The paper is published in the journal Science China Materials.

More information:

Shaojie Chen et al, Recycling of garnet solid electrolytes with lithium-dendrite penetration by thermal healing, Science China Materials (2023). DOI: 10.1007/s40843-022-2371-9

Citation:

Recycling of garnet solid electrolytes with lithium-dendrite penetration by thermal healing (2023, April 21)

retrieved 21 April 2023

from https://techxplore.com/news/2023-04-recycling-garnet-solid-electrolytes-lithium-dendrite.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.