Plant biomass has long attracted attention as an alternative to fossil fuels, with the potential to drive our sustainable future. But it must be suitably dried before it can be used. Now, researchers from Okayama University have developed a new technique that allows for dehydrating plant biomass without the need for thermal drying, generating compressed pellets with superior heat values and squeezed liquids with high concentrations of water-soluble lignin that has potent antiviral activities.

The steady rise in global energy consumption is causing a rapid depletion of fossil fuel resources. Since fossil fuels take thousands of years to replenish, there is an urgent need to determine alternate renewable energy sources. Biomass is a reliable renewable source of energy since it comprises organic matter from plants and animals.

Biomass is readily available in nature and its organic composition makes it a top choice for an environment-friendly energy resource. However, plant biomass contains more than 50% moisture, which needs to be reduced by mechanical methods or through heating and natural seasoning to about 35% for increasing the power generation efficiency when used as fuel. For optimal benefits, this drying process should be fast, economic, and energy efficient.

The current system of mechanical compression is inefficient as it needs a subsequent thermal drying process, which makes the operation energy- and time-consuming and may often involve cumbersome equipment of appreciable cost. Moreover, the squeezed liquid produced as a by-product by most of these methods does not contain water-soluble lignin—an important structural polymer in plant cells with myriads of applications.

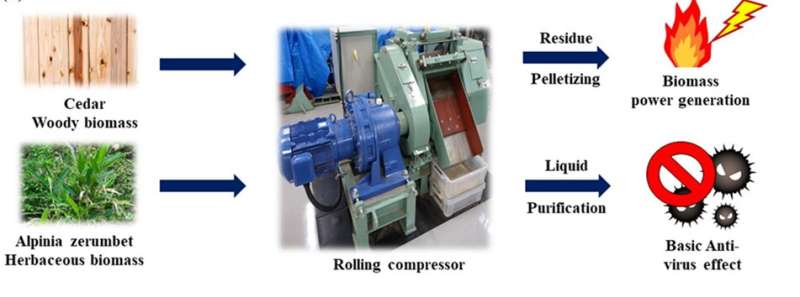

To address these issues, researchers from Japan led by Dr. Toshiaki Ohara, an Assistant Professor in the Department of Pathology and Experimental Medicine, Faculty of Medicine, Dentistry and Pharmaceutical Sciences, Okayama University have identified an effective mechanical compression system for drying plant biomass for power generation without the need for thermal drying. Their novel method can be applied on both woody and herbaceous plants and generates a compression liquid with water-soluble lignin that has basic antiviral properties against influenza and pig epidemic diarrhea viruses.

In their study, the findings of which were published on 22 October 2022 in the Journal of Material Cycles and Waste Management, the researchers used cedar wood board and chips as woody biomass and the ginger herb species Alpinia zerumbet as herbaceous biomass to test the novel mechanical rolling compression method. They found that cedar board and Alpinia zerumbet were compressed more effectively than cedar chips.

Explaining this observation, Dr. Ohara says, “Using our technique, all plants could be compressed; however, cedar board and Alpinia zerumbet were more effectively compressed than cedar chips, which were compressed in a random direction. This indicates that compression along plant vessels, such as straw, is essential for efficacy.” Here, it must be mentioned that plant vessels are tissues in vascular plants associated with the conduction of nutrients and water.

After compression, the researchers crushed and pelletized the residues to determine their combustion performance, an indicator of their potential as biomass for power generation. The liquid obtained as a byproduct of compression was filtered, its lignin content and structure determined, and its antiviral properties evaluated using cell viability assays.

The cedar board pellets showed a higher heat value on combustion, which matched the ISO standards, attesting to their higher energy performance. The ginger herb species yielded more water-soluble lignin, but its heat value on combustion was slightly lower, at 95% of the ISO standards. However, both cedar board and Alpinia zerumbet compression liquids significantly inhibited influenza and porcine epidemic diarrhea virus infection.

Dr. Yuta Nishina from the Research Core for Interdisciplinary Sciences, Okayama University, a co-author of the study, observes, “The non-chemically extracted water soluble lignin obtained by this method can find applications in the fields of medicine, cosmetics, and livestock husbandry.” Besides, the high-carbon content water-soluble lignin may find use in carbon nanomaterial production and contribute to reducing carbon-driven pollution.

Summarizing the benefits of their novel technique, Dr. Ohara observes, “Our method does not require time, a stockyard, or additional thermal drying, allowing for on-site operation. This compressor can squeeze both wood and herbs allowing us to promote biomass electric power generation using locally grown plants. These characteristics are beneficial for advancing local sustainability.”

Toshiaki Ohara et al, A novel mechanical plant compression system for biomass fuel and acquisition of squeezed liquid with water-soluble lignin as anti-virus materials, Journal of Material Cycles and Waste Management (2022). DOI: 10.1007/s10163-022-01531-5

Citation:

Effective compression of plant biomass for alternate fuel and anti-viral applications (2023, January 4)

retrieved 4 January 2023

from https://techxplore.com/news/2023-01-effective-compression-biomass-alternate-fuel.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.