As one of the most promising solutions to improve the utilization efficiency of fossil fuels and alleviate environmental pollution, thermoelectric (TE) power generation technology has the advantages of solid-state operation, working without moving parts, free maintenance, and extended service. Over the past decades, considerable efforts have been made to improve the performance of TE materials. And some excellent alloys appear, such as IV-VI compounds (e.g. SnSe, GeTe, and PbSe), skutterudites, and Cu2Se.

These unprecedented advances in improving the performance of TE materials are an important enabling step that heralds widespread applications of TE devices. However, the advancements in TE device technology have progressed less rapidly. Current efforts are focused primarily on single-leg or unicouple issues, such as the design of electrodes, screening of barrier layers, and interface optimization. A single leg is very useful for assessing the potential of a particular TE material, but is still far from practical applications.

Toward industrial applications, modules consisting of both n-type and p-type TE materials need to be developed. Nevertheless, the development of modules is more challenging than the fabrication of a single leg.

More issues should be elaborately addressed, such as the development of matching n-type and p-type TE materials, geometry optimization of TE legs, welding and assembling of multiple legs, and evaluation of the efficiency and reliability of modules. In addition, most TE components currently being used or studied contain rare elements (e.g. Te) or toxic elements (e.g. Pb), presenting a potential impediment to large-scale applications.

In recent years, Mg3Sb2-based compounds have attracted considerable interest from the TE community due to their nontoxic nature, abundance of constituent elements, and excellent mechanical robustness. Inspired by the transition of p-type Mg3Sb2 into n-type Mg3Sb2, subsequent research into this kind of compound has flourished. Significant progresses have been made over the past five years, achieving improvements in TE performance.

This result makes the low-cost and environmentally friendly Mg3Sb2-based compounds promising substitutes for the state-of-the-art Te- or Pb-containing alloys for medium-temperature TE power generation. And it has recently ignited intensive research interest in their device development.

At a single-leg level, efforts have been made in terms of scalable synthesis of n-type Mg3Sb2, design of reliable junction interfaces, and screening of barrier layers. A noteworthy result is that a single-leg efficiency of ~10% could be achieved at a temperature difference of 400 K with a heat source temperature of 700 K, indicating good potential for medium-temperature power generation applications.

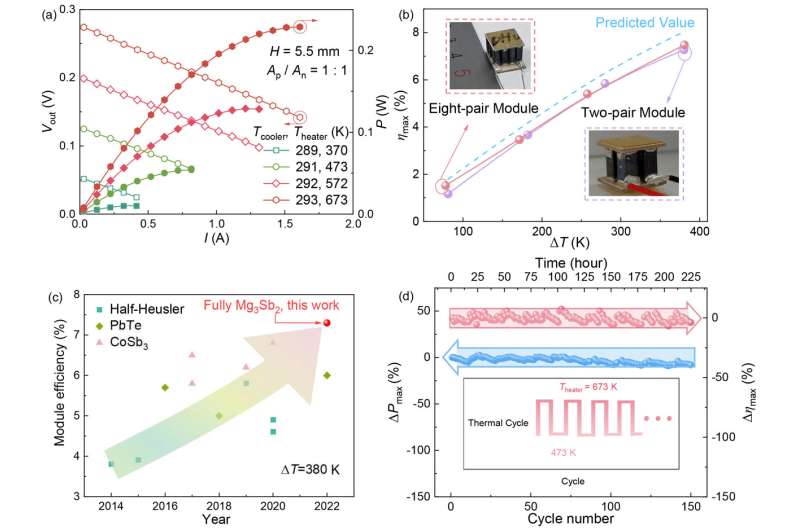

At a unicouple or module level, different p-type TE compounds, such as Bi2Te3, MgAgSb, GeTe, CdSb, and CoSb3, have been used for pairing with n-Mg3Sb2. The modules made from different material combinations have offered outstanding power generation performance in the low and medium temperature range.

However, it is noticeable that these modules are all fabricated using different-parent n- and p-type TE compounds. Due to the different TE and chemical properties of these n- and p-type alloys, cumbersome device geometry design and individually selecting suitable barrier layers are needed.

More critically, TE modules for power generation usually operate at large temperature gradients (e.g. 300~500 K for mid-temperature power generation applications) and fluctuating temperatures, so the differences in physical parameters of n- and p-type TE materials, such as the coefficient of thermal expansion, will result in high thermal stresses that can easily lead to device failure during service.

In addition, the differences in melting point and machinability of different n- and p-type TE materials impose additional constraints on the welding and assembly process.

Therefore, there is a strong desire to develop efficient and robust TE modules using the same parent TE compounds, so that an excellent match of material properties will facilitate module fabrication and ensure long-term stable operation. And it has been well demonstrated in actual applications, for example, the commercially available Bi2Te3 modules, the PbTe modules, and SiGe modules used by NASA in deep space exploration, which are all made from the same parent n- and p-type TE materials.

In response to this challenge, recently, the TE research team led by Professor Wan Jiang and Lianjun Wang from Donghua University (DHU) and Doctor Qihao Zhang from the Leibniz Institute for Solid State and Materials Research Dresden (IFW Dresden) developed novel TE modules consisting of both n-type and p-type Mg3Sb2-based alloys.

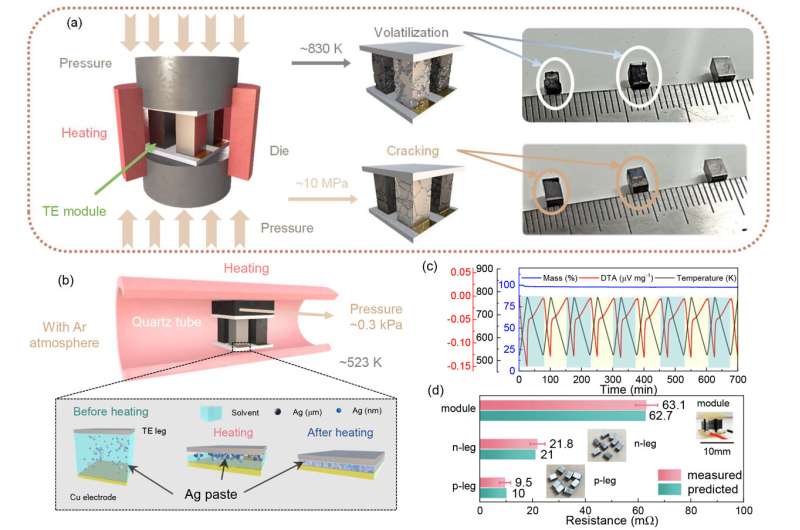

The same-parent p-type and n-type Mg3Sb2-based pellets are fabricated using mechanical alloying and spark plasma sintering. These two compounds show well-matched TE and mechanical properties due to their analogous crystal structures and similar chemical compositions.

Finite element simulations confirm that the optimum leg cross-sectional area ratio to achieve the maximum conversion efficiency is around 1.0, which is favorable for the assembly of the modules. Thermomechanical coupling calculations show that the thermal stresses caused by the difference in thermal expansion between the p- and n-type TE elements are minimized. Iron is used as a diffusion barrier layer for both n-type and p-type legs.

And a one-step sintering process is adopted to fabricate the TE joints, which enables strong bonding with low interfacial contact resistivity. Moreover, all-Mg3Sb2-based TE modules are fabricated by developing a new joining process using Ag composite pastes that allows low-temperature assembly, capable of withstanding higher service temperatures.

All these efforts result in a fully Mg3Sb2-based module with a high efficiency of 7.5% to capture electric energy at a heat source temperature of 673 K and exceptional module reliability against thermal cycles. These results successfully illustrate the great potential of developing all Mg3Sb2-based modules for the efficient generation of electricity from low-grade but extremely abundant waste heat.

The findings are published in the journal National Science Review.

More information:

Meng Jiang et al, High-efficiency and reliable same-parent thermoelectric modules using Mg3Sb2-based compounds, National Science Review (2023). DOI: 10.1093/nsr/nwad095

Citation:

Capturing electricity with an effective and reliable same-parent thermoelectric module (2023, May 31)

retrieved 31 May 2023

from https://techxplore.com/news/2023-05-capturing-electricity-effective-reliable-same-parent.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.