Effective energy storage is paramount to society’s transition to renewable energy. Lithium metal batteries (LMBs) have the potential to double the amount of energy stored in a single charge compared to current lithium ion batteries (LIBs), but lithium dendrite growth and electrolyte consumption in current LMB technologies are hindering battery performance.

Substrates for solid polymer electrolytes (SPEs) offer a potential solution to current LMB limitations, but SPEs require their own optimization prior to integration into all-solid-state LMB (ASSLMB) systems.

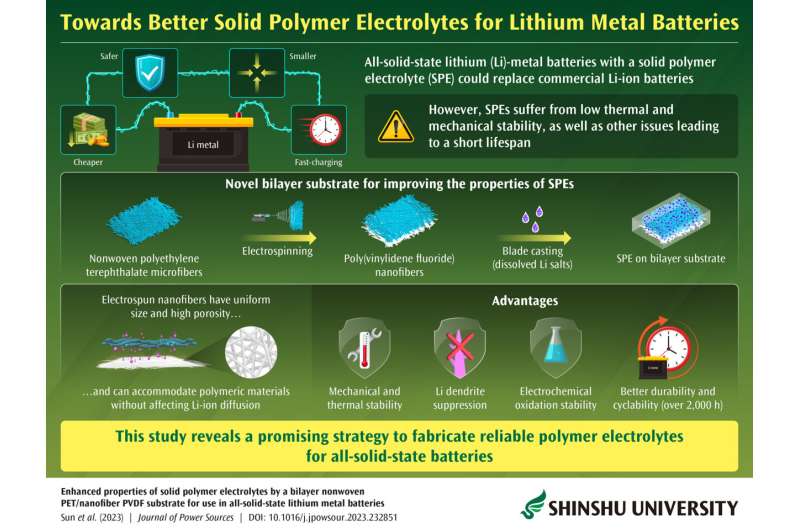

A team of leading scientists from Shinshu University, Kyoto University and Sungkyunkwan University recently reported the development of a bilayer, nonwoven polyethylene terephthalate (PET) microfiber/polyvinylidene fluoride (PVDF) nanofiber membrane using a mechanical pressing method, which acts as a separator for LIB systems to prevent short circuits between electrodes.

The separator demonstrated improved wettability, or ability of the lithium ion-containing electrolyte liquid to come in contact with the electrodes, and thermal stability of the battery system. Importantly, this bilayer membrane can also be used in SPEs of LMB systems to prevent detrimental lithium dendrite growth and structural failure.

In their current research study, the research team generated a similar bilayer, nonwoven PET/PVDF (nPPV) substrate using an electrospinning method to prevent the formation of voids and folds between the two layers that reduce the longevity of the PVDF layer. The study characterized the nPPV-reinforced solid polymer electrolytes (nPPV-SPEs) for mechanical, thermal and electrochemical properties, and testing confirmed that the substrate significantly improved the performance of ASSLMB systems.

The team published their results online in Journal of Power Sources.

“Considering the poor cycling performance (charge-discharge cycles) of SPEs stemming from low mechanical and thermal properties, this project focused on the fabrication of SPEs reinforced by a bilayer substrate comprised of a layer of PET nonwoven fabric and a layer of PVDF nanofibers to improve the structural stability and thus the cycle performance of SPEs,” said Ick Soo Kim, corresponding author of the study and professor at the Nano Fusion Technology Research Group in the Institute for Fiber Engineering (IFES) at Shinshu University.

Importantly, SPEs made up of polymer matrices and lithium salts demonstrate properties such as flexibility and processability that are compatible with LMB electrodes. The electrospinning method also eliminates the folds and voids generated by the pressing method between the PET and PVDF layers, providing a simple, easy and adaptable manufacturing method for nanofiber membranes.

“The nanofibers produced using industrial scale electrospinning equipment by LEMON CO., Ltd. ensure small and uniform pore size with high porosity, thus accommodating polymeric materials and lithium salts without affecting ion diffusion and improving electrochemical oxidation stability,” said Kim.

For this study, PVDF nanofibers were electrospun directly onto the microfiber PET layer to produce a more robust bilayer material. Improved structural stability allows SPEs to bear the chemical reactions occurring in the system during longer-term charging and recharging cycles.

“The bilayer substrate significantly improves the mechanical and thermal properties of solid polymer electrolytes, which enables the cell to operate over 2000 hours,” said Kim. Moreover, the high tensile strength of the material suppresses lithium dendrite growth, one of the significant challenges of LMB systems.

Despite advances in SPE technology, the research team acknowledges that more work is required to realize the potential of solid state electrolytes (SSEs) like SPEs.

“The improved structure stability of SPEs ensures a long lifespan and safe use of lithium batteries, but the rate performance and lithium mobility of SPEs are still inferior to liquid electrolytes in lithium ion batteries. The next step is improving the ionic conductivity to meet the requirements of fast charge and discharge,” said Kim. The researchers predict that additional substrates will be studied to further enhance the electrochemical properties of SPEs and advance ASSLMB system technology.

More information:

Lei Sun et al, Enhanced properties of solid polymer electrolytes by a bilayer nonwoven PET/nanofiber PVDF substrate for use in all-solid-state lithium metal batteries, Journal of Power Sources (2023). DOI: 10.1016/j.jpowsour.2023.232851

Provided by

Shinshu University

Citation:

Bilayer PET/PVDF substrate-reinforced solid polymer electrolyte improves solid-state lithium metal battery performance (2023, March 22)

retrieved 22 March 2023

from https://techxplore.com/news/2023-03-bilayer-petpvdf-substrate-reinforced-solid-polymer.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.