A research team has successfully developed an environmentally friendly refrigerant compressor using an electrochemical method instead of a mechanical method. The development is published in Renewable Energy.

In contrast to conventional refrigerants containing HFCs (hydrofluorocarbons) that destroy the ozone layer and cause global warming, environmentally friendly refrigerants (ammonia, R1234yf, etc.) have very small environmental impacts. In accordance with the Kigali Amendment to the Montreal Protocol, advanced nations in Europe as well as the United States and Japan are in the process of transitioning to eco-friendly refrigerants until the complete phase-out of the use of HFCs in 2024. Using environmentally friendly refrigerants can help to prevent environmental pollution and contribute to sustainable development.

Mechanical compressors have several limitations, such as problems with durability of parts due to rapid rotation, contamination of refrigerants caused by lubricants, and loud noise. As electrochemical compressors have no moving parts and do not require the use of lubricants, they can help to overcome the shortcomings of conventional mechanical compressors. In addition, a constant flow rate can be provided at various pressure ratios with electrochemical compressors, and the high efficiency can help to significantly increase the COP (coefficient of performance) of the heat pump.

To maximize the energy-saving effect of the rooftop greenhouse, the research team developed an “optimized smart farm operating solution” capable of controlling every aspect of the system such as air conditioning, LED, and hydroponics system in accordance with external weather conditions, and plans to demonstrate this solution through the demonstrated rooftop greenhouse.

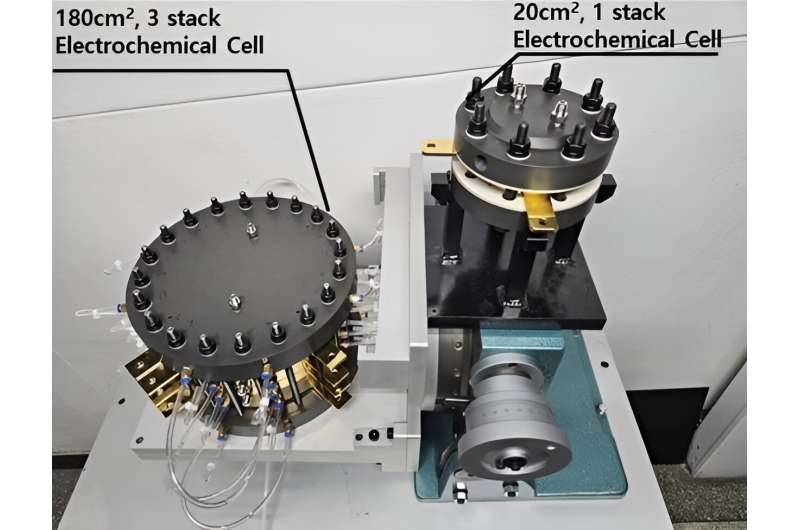

The joint research team has secured the core technologies necessary for producing the environmentally friendly electrochemical refrigerant compressor and for designing the system and has successfully implemented the test run. With the newly developed environmentally friendly electrochemical refrigerant compressor, the desired flow rate and pressure can be obtained by stacking.

Unlike conventional mechanical compressing, an electrochemical compressor compresses refrigerants through the movement of ions by charging the ion exchange membrane with DC (direct current) voltage, while using hydrogen as the carrier gas. Additionally, it also allows for isothermal compression by applying a multi-layer freezing technology where cells are accumulated in a stack configuration.

To date, the refrigerants that have been successfully compressed are ammonia, a natural refrigerant, and R1234yf, an eco-friendly refrigerant. The joint research team designed cells capable of operating solidly even under repeated high-pressure conditions and also demonstrated a leak-free design to prevent the leakage of refrigerants at high pressure.

In addition, by designing a channel capable of producing high performance even at high voltage, the joint research team has succeeded in maximizing the compression efficiency of the electrochemical compressor.

The electrochemical compressor is capable of offering the desired compression ratio regardless of size and can provide a stable flow rate in accordance with the compression ratio with excellent efficiency. Therefore, it can be used not only for constructing high-efficiency plants and heat pumps but also for building small-scale systems. In particular, as an electrochemical ammonia compressor can be used for compressing ammonia even when the ammonia acts as a hydrogen carrier, it can also be used for constructing hydrogen infrastructure.

The joint research team was led by Principal Researcher Young Kim of the Korea Institute of Machinery and Materials (KIMM), an institute under the jurisdiction of the Ministry of Science and ICT, and professors Min-sung Kim and Dong-kyu Kim of Chung-Ang University

Young Kim says, “The eco-friendly electrochemical refrigerant compressor is highly efficient and requires a small footprint, which makes it economically attractive.” Dr. Kim added, “We are planning to develop a heat pump system using this technology to contribute to the achievement of the goal of going carbon neutral by 2050.”

More information:

Min Soo Kim et al, Parametric study on the performance of electrochemical hydrogen compressors, Renewable Energy (2022). DOI: 10.1016/j.renene.2022.09.081

Citation:

An environmentally friendly electrochemical refrigerant compressor (2023, November 24)

retrieved 25 November 2023

from https://techxplore.com/news/2023-11-environmentally-friendly-electrochemical-refrigerant-compressor.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.