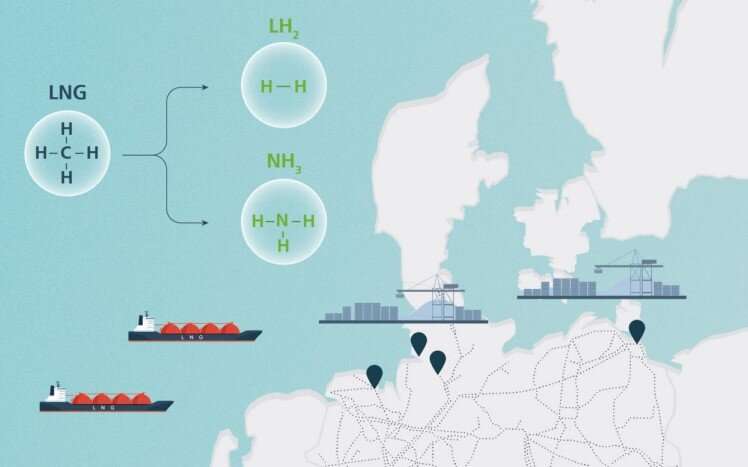

The construction of new LNG terminals with the aim of reducing energy dependence on Russian natural gas raises concerns that the associated fossil fuel infrastructure could hinder the transition of the energy system to renewable energy sources and thus the energy transition. Therefore, the question of convertibility of these LNG terminals for a later use with renewable energy carriers such as liquid hydrogen or ammonia is of particular importance.

A new study by Fraunhofer ISI on behalf of the European Climate Foundation (ECF) addresses this question and finds that there is much uncertainty around the proposed conversion of LNG terminals to import liquid hydrogen or ammonia.

The Russian attack on Ukraine heavily increased the concern on energy security due to the ongoing dependency of most EU Member States on Russian natural gas and oil. As a consequence, these states are in search of alternative gas sources such as liquefied natural gas (LNG) imported from countries such as the U.S., Canada, or Qatar via ship.

The short-term use of Floating Storage and Regasification Units (FSRUs) is a flexible way of bringing in gas to meet needs in the winter. However, the construction of fixed onshore terminals with projected lifetimes reaching into the 2040’s raises concerns of stranded assets and fossil fuel lock-ins, as LNG is not climate-neutral.

A prospective solution to use the onshore terminals long-term is to adapt their components to potentially climate-neutral energy carriers, such as liquid hydrogen or liquid ammonia. But their physical properties impose technical challenges and the know-how on the costs for converting LNG terminals is limited. In this context, the new Fraunhofer ISI study “Conversion of LNG Terminals for Liquid Hydrogen or Ammonia” sheds some light on the technical feasibility of converting LNG terminals under economic considerations through a dedicated literature research that was complemented by a dozen experts from academia and industry.

Converting parts of LNG terminals is feasible if considered in the design

Both ammonia and liquid hydrogen pose technical challenges on the terminal infrastructure. Ammonia has a more favorable boiling temperature than LNG and therefore lower thermal insulation requirements, but it is corrosive and toxic. Liquid hydrogen on the other hand has an even lower boiling point than LNG, can cause material embrittlement and has high safety requirements due to explosion risks.

LNG terminals consist of several components such as a storage tank, compressors, and pumps. The storage tank is the most expensive part. To avoid high new investments, the conversion to ammonia or liquid hydrogen should already be considered when designing the terminals, for example by using compatible materials like special stainless steel. Given this, it is estimated that approximately 70% of the LNG terminal investment can be further used for an ammonia terminal.

For liquid hydrogen, next to material compatibility, additional thermal insulation of the tank is required or a higher boil-off has to be accepted. Economic impacts are more difficult to estimate due to lack of industrial scale infrastructure experiences. However, based on the share of cost of the LNG tank, it can be projected, that approximately 50% of the LNG terminal investment can be further used, if material compatibility has been considered in tank’s construction and a higher boil-off is accepted.

Switching between energy carriers is not feasible without substantial adaptations

Although LNG infrastructure is sometimes termed as ammonia or hydrogen “ready,” the conversion will nonetheless require substantial technical adjustments with economic impacts. It is not feasible to operate the dedicated terminal components with different energy carriers at the same time or flexibly move from one to another without adaptions. In the case of liquid hydrogen, the lack of practical large-scale implementations—there is only one smaller scale prototype import terminal in Kobe, Japan—and little to no current demand or market for liquid hydrogen creates more unpredictability.

Matia Riemer, co-author of the study, underlines the uncertainty of the feasibility to continue to use LNG import terminals in climate-neutral energy systems: “Currently, it is not clear whether the terminals will not end up as stranded assets. To limit this risk, a concept for the terminal’s conversion to other energy carriers should already be part of the design phase and taken into account in selection of materials and location. “

Feasibility depends also on location and infrastructure

Dr. Florian Schreiner, who coordinated the project at Fraunhofer ISI, states, “The question of the feasibility to convert LNG terminals to liquid hydrogen or ammonia terminals depends on many factors: Firstly, future demand for both energy carriers is uncertain and we need more reliable demand projections to improve planning security. Furthermore, the feasibility also depends on the individual characteristics of terminals and their location. For example, the existence of industrial parks in the neighborhood to ex-change valuable waste energy flows or distribution infrastructure such as pipelines is an important criterion.”

Therefore, bringing together industry, infrastructure developers, academia, politics as well as other stakeholders is seen as vital to both avoid fossil lock-ins and improve investor planning security, as the infrastructure will be used for decades and plays an important role in the context of a conversion of the energy system to become climate-neutral in the future.

Report (PDF): Conversion of LNG Terminals for Liquid Hydrogen or Ammonia: Analysis of Technical Feasibility under Economic Considerations

Provided by

Fraunhofer-Institut für System- und Innovationsforschung (ISI)

Citation:

A climate-neutral future for converted LNG terminals? (2022, November 3)

retrieved 3 November 2022

from https://techxplore.com/news/2022-11-climate-neutral-future-lng-terminals.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.