NIMS and Osaka University Graduate School of Engineering have succeeded in fabricating a nickel single crystal with only a very few crystalline defects by irradiating nickel powder with a large-radius, flat-top laser beam (i.e., a laser beam whose intensity is uniform across a cross-section of the beam). This technique may be used to fabricate a wide variety of single-crystalline materials, including heat-resistant materials for jet engines and gas turbines.

Previous studies have reported that single crystals can be fabricated using electron beam additive manufacturing. However, this technique requires expensive equipment and its operation is also costly due to the need to create a vacuum, limiting its widespread use. Although laser additive manufacturing can be performed using cheaper equipment, previous efforts to fabricate single crystals using this technique had failed. When a raw metal powder material is irradiated with a laser beam, it melts, forming a solid–liquid interface. It had been difficult to grow grains near the interface in the same direction and to prevent the formation of strain-inducing defects caused by their solidification.

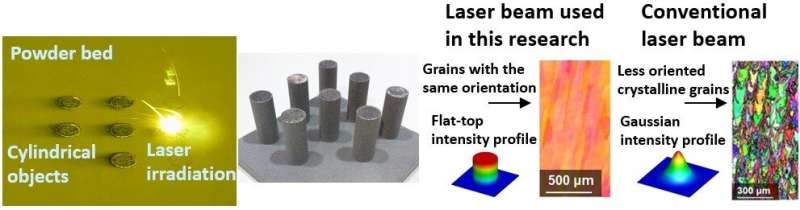

This problem was found to be attributed to the intensity profile of conventional Gaussian laser beams (i.e., laser beams with a bell-shaped intensity across a cross-section of the beam), which causes the formation of polycrystals composed of less oriented crystalline grains with many grain boundaries.

This NIMS–Osaka University Graduate School of Engineering research team succeeded in fabricating single crystals using a flat-top laser beam, forming a flat melt pool surface on the nickel powders. Individual crystalline grains grew in the same direction with fewer strain-inducing defects. Single crystals without grain boundaries, which are susceptible to cracking, are very strong at high temperatures. This new technique provides a way to minimize strain generation and cracking of crystals during their solidification. In addition, this technique does not require the use of seed crystals, simplifying additive manufacturing processes.

In addition to nickel, this laser additive manufacturing technique can be used to process other metals and alloys into single-crystalline objects. Jet engine and gas turbine components are becoming more complex in shape and lighter, and demand for additive manufacturing of these components using heat-resistant nickel-based superalloys is growing. Because single crystals are stronger than polycrystals at high temperatures, their practical use as heat-resistant materials is promising. Global R&D efforts to achieve this using cheaper and widely used laser additive manufacturing technology is expected to intensify rapidly.

This research was published in Additive Manufacturing Letters.

Dennis Edgard Jodi et al, Manufacturing single crystals of pure nickel via selective laser melting with a flat-top laser beam, Additive Manufacturing Letters (2022). DOI: 10.1016/j.addlet.2022.100066

Citation:

3D printing nickel single crystals using laser additive manufacturing technology (2022, July 12)

retrieved 12 July 2022

from https://techxplore.com/news/2022-07-3d-nickel-crystals-laser-additive.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

Stay connected with us on social media platform for instant update click here to join our Twitter, & Facebook

We are now on Telegram. Click here to join our channel (@TechiUpdate) and stay updated with the latest Technology headlines.

For all the latest Technology News Click Here

For the latest news and updates, follow us on Google News.